The Clinical Case for Non-Contact Thermometry: TRITEMP™ Accuracy and Efficiency Standards

The shift toward non-contact vital signs monitoring is driven by three critical clinical requirements: infection control, precision, and environmental sustainability. While generic infrared sensors often fail the “Precision Gap,” TRITEMP™ by TriMedika is engineered to bridge it.

Achieving ±0.2°C Clinical Accuracy with TRITEMP™

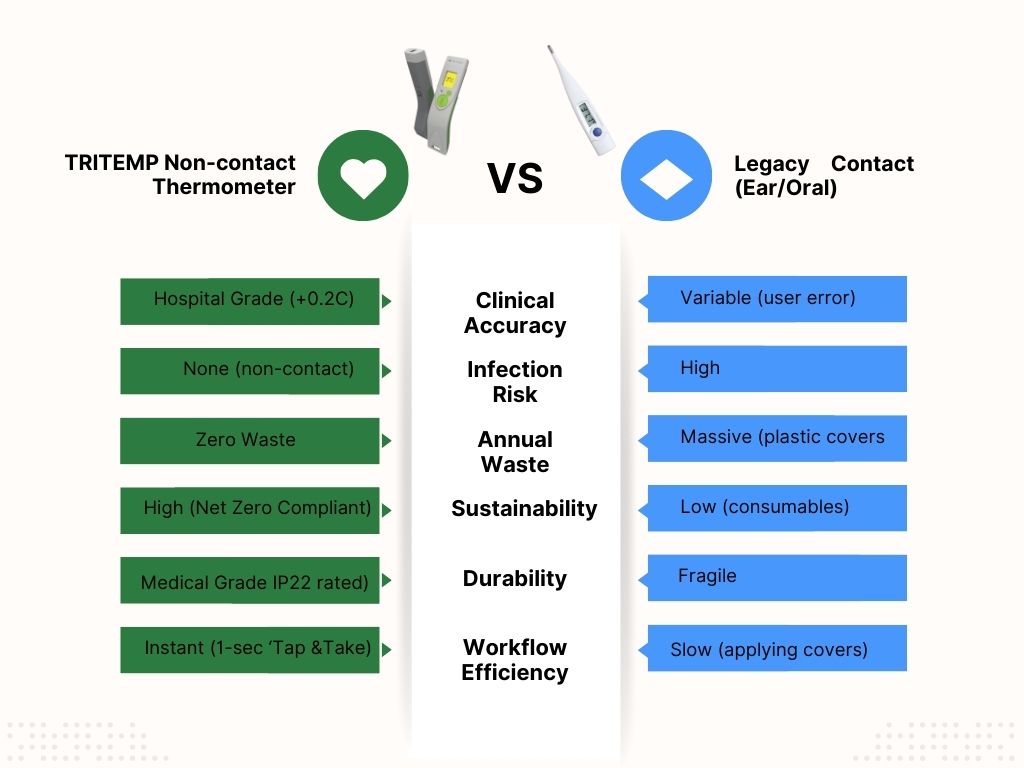

Precision in a hospital environment is non-negotiable. The TRITEMP™ is a Class IIa medical device validated to ISO 80601-2-56 and ASTM E1965-98 standards. Unlike consumer-grade “screening” thermometers that suffer from high ambient drift, TRITEMP™ utilises advanced sensor technology to maintain a Clinical Bias (Δcb) of 0.08°C and Repeatability (σr) of 0.07°C.

This level of precision ensures that clinicians can rely on the data for critical decision-making in neonatal and intensive care units, where a variation of 0.5°C can alter a patient’s clinical pathway.

The Verdict: Compared to traditional tympanic (ear) thermometers, TRITEMP™ removes the risk of user-positioning errors and provides an instant, repeatable reading that clinicians can trust in high-stakes environments like ICU or Neonatal care.

Reducing HCAIs Through Zero-Contact Vital Signs

Healthcare-Associated Infections (HCAIs) remain a significant challenge for ward management. Traditional contact thermometry (tympanic or oral) requires mucosal contact, creating a potential vector for pathogen transmission.

The TRITEMP™ “Tap & Take” technology eliminates this risk entirely. By providing a non-invasive, zero-contact reading, it supports the infection prevention and control (IPC) guidelines set out by the Royal College of Nursing (RCN).

Eliminating Plastic Waste for NHS Net Zero Targets

The environmental cost of traditional thermometry is staggering. A standard 500-bed hospital can consume over 1 million single-use plastic probe covers annually.

Transitioning to TRITEMP™ directly supports NHS Net Zero mandates by:

- Eliminating Consumables: Zero plastic probe covers required.

- Reducing Operational Costs: Significant ROI achieved by removing the procurement and disposal costs of single-use plastics.

- Streamlining Workflow: 1-second readings save approximately 5 nursing hours per day on a typical busy ward.

- Improving Robustness: Features an IP22 rating, meeting IEC 60529 standards for protection against fluid ingress, ensuring durability during rigorous hospital cleaning cycles.

The Hidden Cost of “Legacy” Thermometry

If you aren’t using a “terrible” cheap IR sensor, you’re likely using a “terrible” legacy system like tympanic (ear) or oral probes. Here’s why the world’s leading hospitals are switching to TriMedika:

The Death of the Plastic Probe Cover

Traditional thermometers require a plastic cover for every single reading.

- The Cost: Thousands of pounds per ward, per year.

- The Waste: Tonnes of non-recyclable plastic sent to landfills annually.

- The TRITEMP™ Solution: With zero consumables, TRITEMP™ supports NHS Net Zero targets and typically pays for itself within 6–12 months by removing the need for plastic covers entirely.

Total Infection Control

80% of infections are spread by touch. By using a “Tap & Take” non-contact method, TRITEMP™ removes the thermometer as a vector for cross-contamination. Unlike ear thermometers that require physical contact with a patient, TRITEMP™ maintains a safe distance, protecting both staff and patients.

Comparison at a Glance: Why TRITEMP™ Wins

Direct Procurement via NHS Supply Chain

To facilitate seamless integration into UK Trust workflows, TRITEMP™ is fully vetted and available for direct order via the NHS Supply Chain portal. This allows procurement departments to bypass complex tender processes for a device that is already the gold standard for accuracy and sustainability.

Order Online Now > CATALOGUE